The wrong hose choice can shut down your entire production line. When engineers select inappropriate hoses for their systems, they face catastrophic failures that cost thousands in repairs and lost productivity. Many facilities learn this lesson the hard way after experiencing burst hoses or system malfunctions during critical operations.

Understanding the Flexible Hose Advantage

Flexible hose systems offer remarkable adaptability across diverse industrial applications. These hoses bend around obstacles whilst maintaining consistent flow rates. Their construction allows movement without compromising structural integrity. Most flexible hoses handle moderate pressures effectively. Temperature tolerance varies significantly between different flexible hose materials and designs.

Hydraulic hose systems serve different purposes in manufacturing facilities compared to flexible alternatives. These specialized hoses handle high-pressure applications that flexible options cannot manage safely. The reinforced construction withstands extreme operating conditions consistently. Manufacturing processes often demand the reliability that hydraulic hoses provide. Understanding these applications prevents costly equipment selection mistakes.

Hydraulic Hose Performance Under Pressure

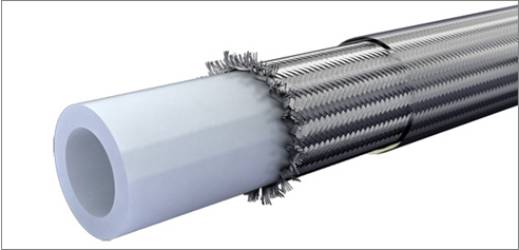

Hydraulic hose construction focuses on withstanding extreme pressures and demanding conditions. These hoses feature reinforced layers that handle thousands of PSI safely. The multi-layer design includes braided wire or textile reinforcement. Inner tubes resist chemical degradation from hydraulic fluids. Outer covers protect against environmental damage and abrasion.

Construction equipment relies heavily on hydraulic hose systems for operation. Mobile machinery faces constant movement and pressure variations. The robust construction handles these challenges without compromising performance. Aerospace applications demand hydraulic hoses that meet strict safety standards. Chemical processing plants require hoses that resist corrosive substances.

Pressure Requirements Drive Selection Decisions

Pressure ratings separate flexible and hydraulic hoses into distinct categories. Standard flexible hoses typically handle pressures up to 300 PSI comfortably. Hydraulic hoses regularly operate at pressures exceeding 5,000 PSI. The construction methods create these performance differences. Multi-layer reinforcement in hydraulic hoses distributes pressure loads effectively.

Your system pressure determines which hose type prevents failures. Low-pressure applications benefit from flexible hose cost savings. High-pressure systems require hydraulic hose engineering and construction. Medium-pressure applications might accept either option with proper specifications. Safety margins matter more than initial cost considerations.

Temperature Considerations Affect Material Selection

Operating temperatures influence hose material selection significantly. Flexible hoses using rubber compounds handle moderate temperature ranges well. Extreme heat degrades standard rubber materials quickly. Cold temperatures make some flexible hoses brittle and prone to cracking. Material selection becomes critical for temperature-sensitive applications.

Hydraulic hoses often incorporate synthetic materials for temperature resistance. High-temperature hydraulic applications require specialised compounds and construction techniques. Steam applications push both hose types to their limits. Food processing demands temperature resistance alongside hygiene requirements. Your temperature range narrows the available options considerably.

Chemical Compatibility Prevents Catastrophic Failures

Chemical resistance varies dramatically between hose types and materials. Flexible hoses might use materials unsuitable for aggressive chemicals. Hydraulic hoses designed for specific fluids resist degradation effectively. Incompatible materials dissolve or swell when exposed to certain chemicals. This compatibility issue causes sudden failures without warning.

Testing chemical compatibility prevents expensive mistakes and safety hazards. Material data sheets provide compatibility information for common chemicals. Unknown chemicals require testing before hose installation. Mixing incompatible chemicals with hose materials creates dangerous situations. Safety considerations outweigh cost savings in chemical compatibility decisions.

Installation Requirements Shape Practical Choices

Installation environments often dictate hose selection beyond technical specifications. Flexible hoses install easily in tight spaces with multiple bends. Hydraulic hoses require careful routing to prevent kinking and damage. Assembly requirements differ significantly between hose types. Professional installation becomes necessary for complex hydraulic systems.

Maintenance access affects long-term operational costs and convenience. Flexible hoses allow easier replacement in confined spaces. Hydraulic hose assemblies might require system shutdown for replacement. Planning installation routes during design prevents future maintenance problems. Access considerations influence total cost of ownership calculations.

Cost Analysis Beyond Initial Purchase Price

Initial costs tell only part of the financial story. Flexible hoses typically cost less upfront than hydraulic alternatives. Replacement frequency affects long-term operational expenses significantly. Hydraulic hoses last longer under appropriate conditions. System downtime costs often exceed hose replacement expenses.

Quality differences within each category create price variations. Premium flexible hoses might cost more than basic hydraulic options. Performance requirements justify higher initial investments frequently. Failure costs include replacement parts, labour, and lost production time. Your budget analysis should include all relevant cost factors.

Industry-Specific Requirements Guide Selection

Different industries face unique challenges that influence hose selection. Construction equipment operates in harsh outdoor environments. Manufacturing plants require consistent performance under controlled conditions. Food processing demands hygiene alongside performance specifications. Each industry has established standards and best practices.

Automotive manufacturing uses both hose types for different applications. Assembly lines require reliable performance to maintain production schedules. Quality control standards affect acceptable hose specifications and suppliers. Understanding industry requirements prevents specification errors and compliance issues.

Safety Standards Cannot Be Compromised

Safety regulations vary between industries and applications. Hydraulic systems pose higher safety risks due to pressure levels. Proper hose selection prevents accidents and regulatory violations. Training requirements differ for hydraulic versus flexible hose systems. Documentation requirements ensure compliance with safety standards.

Emergency shutdown procedures depend on hose system design. High-pressure failures create dangerous situations requiring immediate response. Safety equipment requirements vary with system pressure and chemical hazards. Your safety analysis should include worst-case failure scenarios. Regulatory compliance affects insurance costs and legal liability.

Making the Right Choice for Your Application

System requirements determine the optimal hose selection approach. Pressure, temperature, and chemical compatibility form the foundation criteria. Environmental conditions add complexity to the selection process. Budget constraints influence material and quality choices. Professional consultation prevents costly specification errors.

Testing prototypes under actual operating conditions validates selection decisions. Monitoring performance during initial operation identifies potential issues early. Documentation of selection criteria helps future maintenance and replacement decisions. Your systematic approach reduces risks and operational costs.

Conclusion

Selecting between flexible and hydraulic hoses requires careful analysis of operating conditions, pressure requirements, and environmental factors. The wrong choice leads to system failures, safety hazards, and unnecessary expenses. Understanding the fundamental differences between these hose types enables informed decisions that protect equipment and personnel whilst maintaining operational efficiency.

Ready to specify the right hose for your application? Contact industrial hose specialists who understand your specific requirements and can recommend proven solutions that deliver reliable performance under your operating conditions.

Featured Image Source: https://www.jreltd.com/images/ptfe-hoses/pic1.jpg